ELECTRO-DISCHARGE MACHINING (EDM)

ELECRO-DISCHARGE MACHINING (EDM)

It is also known as Spark-over initiated discharge machining or spark erosion or spark machining.

It is the most probably used electrical machining method.

EDM is used for any material, which is an electrical conductor.

Material Removal Rate (MRR) and finishing of the resulting surface can be controlled by proper energy variation and spark discharge duration.

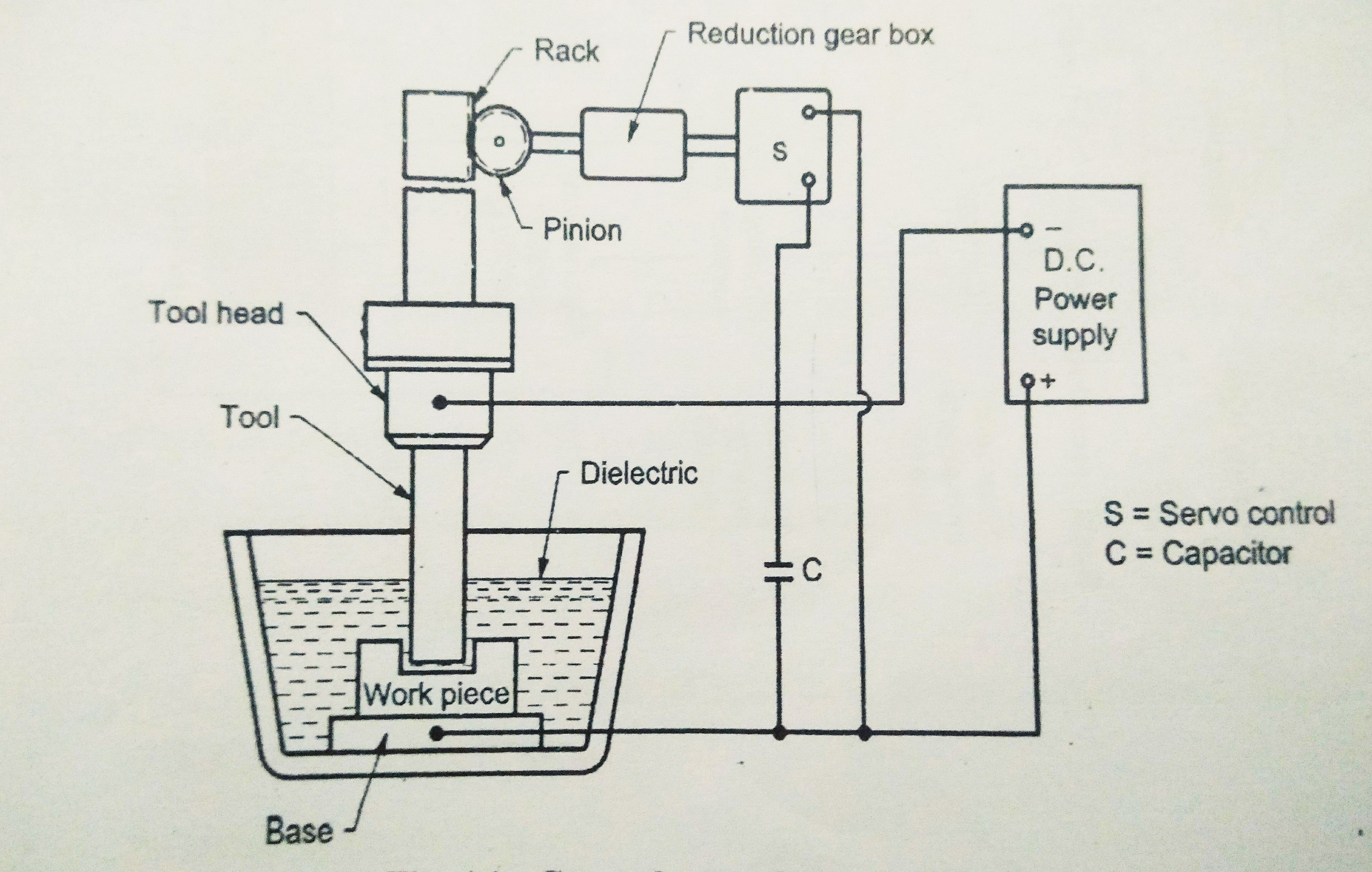

Working :-

When a voltage of 50V to 450V is applied by the circuit, electron starts following from the tool (cathode) due to electric field and the gap is ionised.

Due to this, there is drop in resistance and electric energy which results in electrical breakdown.

As the temperature is very high, the metal gets melt and some portion of it may be vaporized also.

These vaporised or melted particles of the metal are thrown away by the flowing dielectric.

The machining speed of this process is mentioned in terms of an amount of metal removal.

Specification:

Tool material used - The tool (electrode) used is made of materials like brass, copper, cast iron, tungsten, graphite, steel, etc.

Because these materials have properties like ;

- High wear resistance.

- High MRR

- Good conductor of electricity

- Easy to machine ability

Advantages of EDM :-

- As in EDM process there is no direct contact between tool and workpiece, hence highly complicated sections and weak materials can be machined without distortion.

- Any shape which is on the tool surface can be easily reproduced on the workpiece.

- It can be used for any hard material and even in heated treated conditions.

Disadvantages of EDM :-

- Only small workpiece can be machined easily.

- Materials which are only good conductor of electricity can be machined.

- EDM is having low MRR.

- Power required to drive the machine is high.

Applications :-

Mainly EDM is used in tool and die manufacturing because in EDM process hardened materials can be machined easily.

EDM is also used in automobile industries.

Internal threads and internal gears can be cut in harden materials.

Thanks guys i will be posting more stuff like this so please follow and stay tunned.

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by lucifer from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, someguy123, neoxian, followbtcnews, and netuoso. The goal is to help Steemit grow by supporting Minnows. Please find us at the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you would like to delegate to the Minnow Support Project you can do so by clicking on the following links: 50SP, 100SP, 250SP, 500SP, 1000SP, 5000SP.

Be sure to leave at least 50SP undelegated on your account.