Effects of manufacturing processes

Effects of manufacturing processes

The ability to achieve a certain tolerance or surface is a function of the manufacturing process. In this post, I will describe the general capabilities of different processes in terms of tolerance, roughness, and integrity of the surface.

Tolerances and manufacturing processes

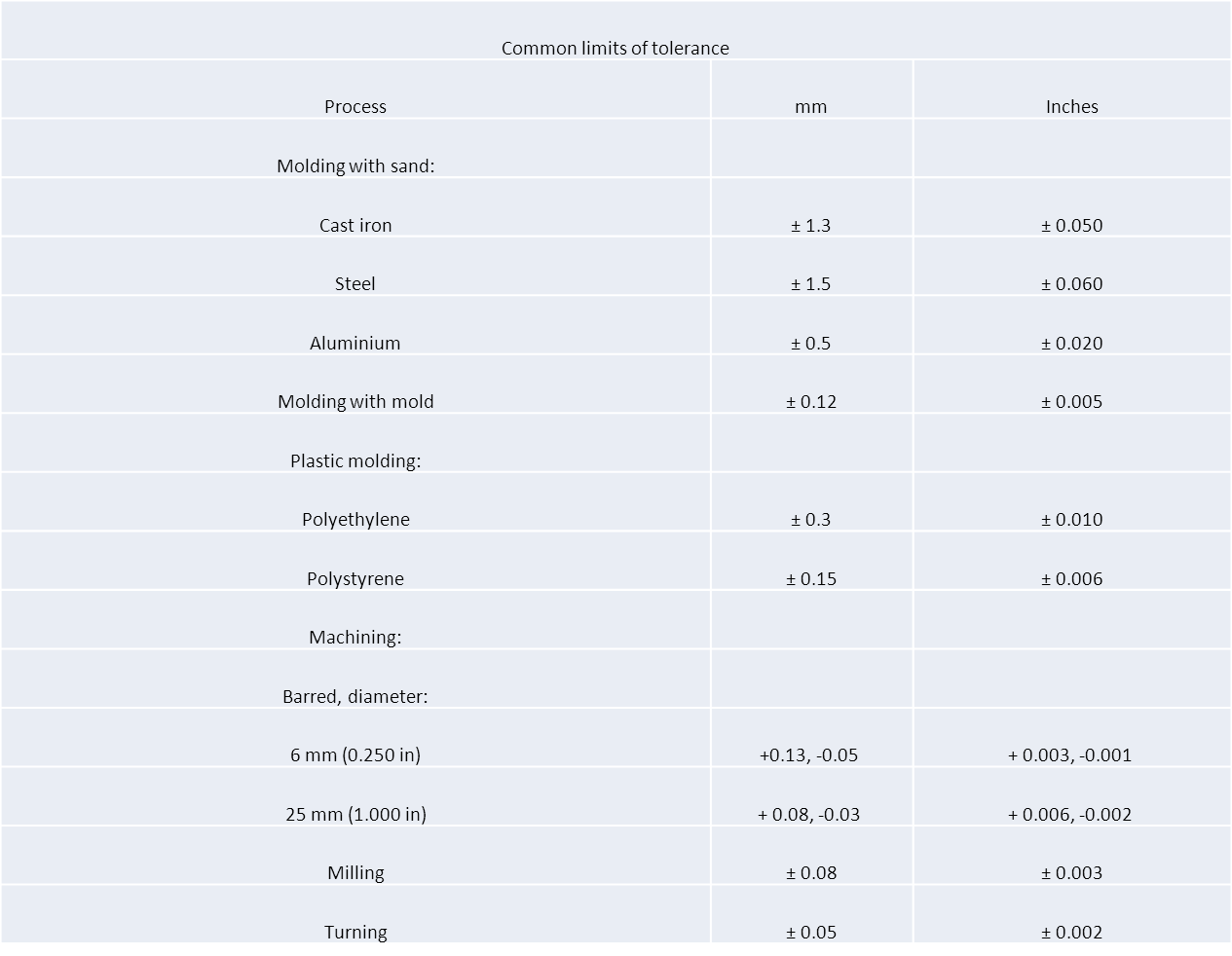

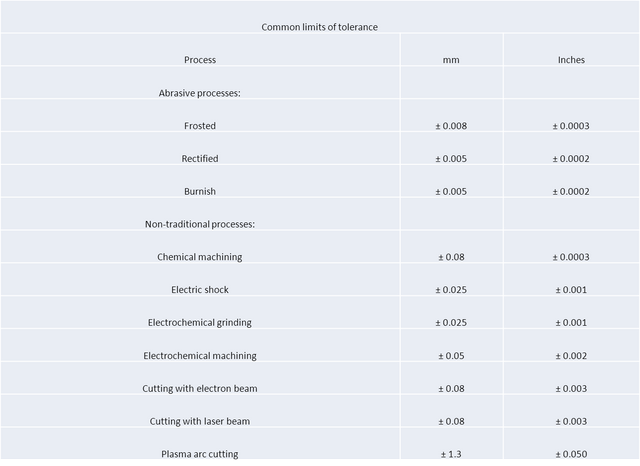

Certain manufacturing processes are inherently more accurate than others. Most machining processes are very accurate, capable of reaching tolerance of ± 0.05 mm (± 0.002 in) or better. In contrast, sand castings are generally inaccurate and tolerances of 10 to 20 times those used for machined parts must be specified. The following table lists a variety of manufacturing processes and indicates the common tolerances for each process. The tolerances are based on the capacity of the processes for the particular manufacturing operation.

The tolerance that must be specified is a function of the size of the piece; The larger the pieces, the more generous the tolerances. The table lists tolerances for parts of moderate size in each processing category.

Surfaces and manufacturing processes

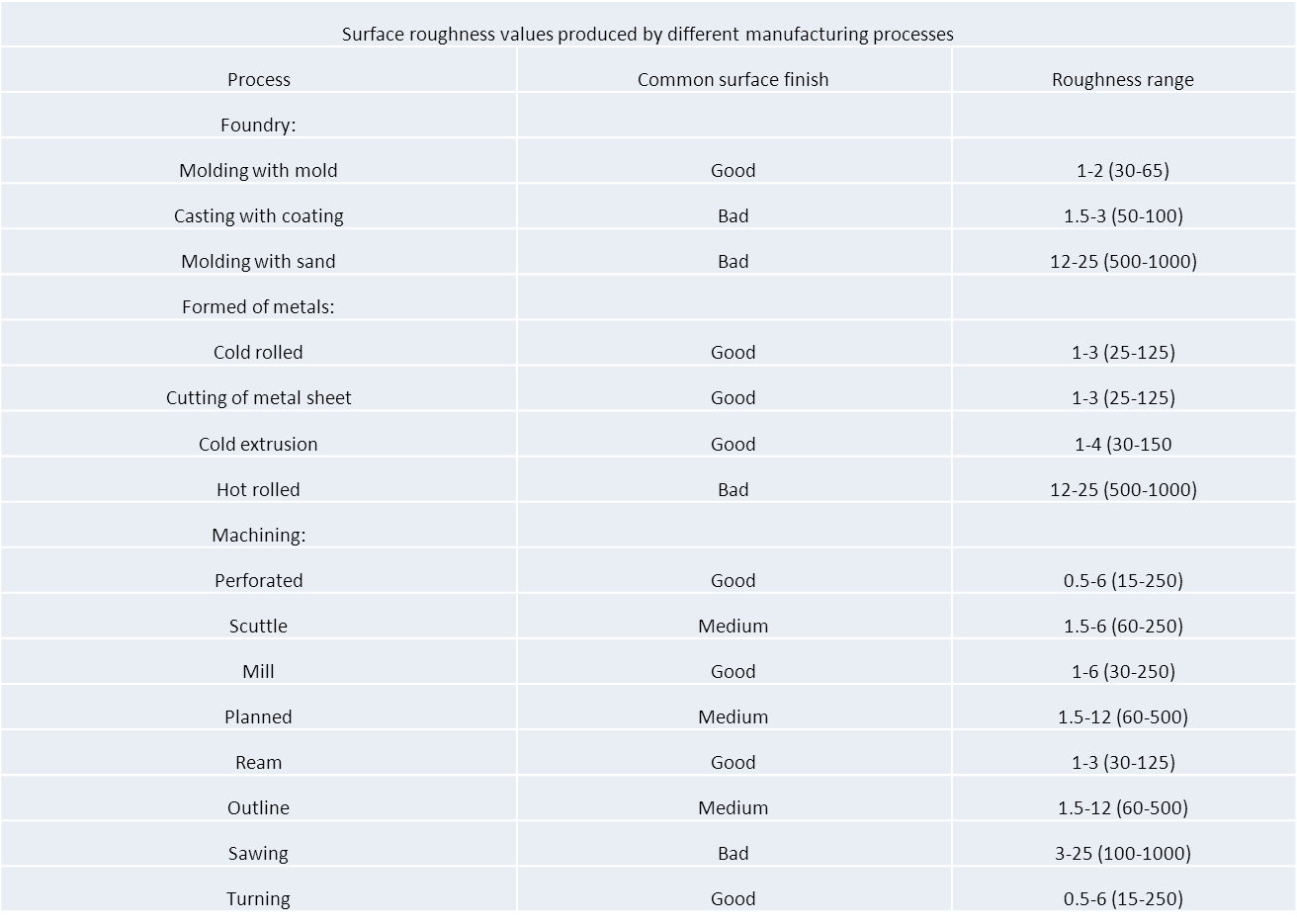

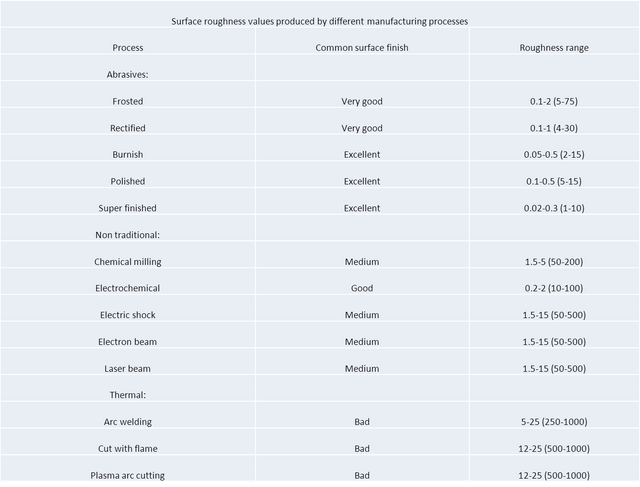

The manufacturing process determines the surface finish and the integrity of the surface. Some processes are inherently more capable than others of producing better surfaces. In general, the cost of processing increases with the improvement of surface finish. This is because getting better surfaces usually requires additional operations and more time. The specific processes to provide superior finishes include burnishing, grinding, polishing and superfinishing. The following table shows the usual surface roughness expected from various manufacturing processes.

For more information visit the following links

- https://www.sciencedirect.com/science/article/pii/S0360319911015631

- http://www.machinedesign.com/materials/working-dimensional-tolerances

- https://www.zygo.com/?/met/profilers/surfaceroughnessmeasurement.htm