Application of lipase from the physic nut (Jatropha curcas L.) to a new hybrid (enzyme/chemical) hydroesterification process for biodiesel production

Hi, this is my first post about science, I want to show you a paper that I do for a seminar at my university. I hope you like it and help me with your vote.

The aim of this study was to characterize a new plant enzyme (with high lipase activity) extracted fromgerminated physic nut seeds, and to apply this lipase to the production of biodiesel using a new processof enzyme/chemical hydroesterification. The lipase activity was detected only in the vegetable enzymeextract from germinated seeds (VEEG). Similar activities were obtained for substrates with differentlengths of fatty-acid chains (111 ± 19 U/g for tributyrin (C4:0), 106 ± 49 U/g for tricaprylin (C8:0), and96 ± 4 U/g for olive oil (C18:1)). The VEEG, obtained by a controlled processes of seed germination, wasable to hydrolyze a wide range of biodiesel raw materials (vegetable oils, tallow, and biodiesel waste);of these, soy and physic nut oil showed especially high hydrolysis conversion (97% FFA). The biodiesel(fatty acid methyl esters) was produced by the hydrolysis of the physic nut oil using the VEEG, andsubsequent esterification of the generated fatty acids with methanol by heterogeneous acid catalysis(niobic acid in pellets). The resulting biodiesel was of excellent quality, with the following properties:viscosity (5.5 mm2/s), ester content (97.1%), total glycerol (0.09 % w/w), max. methanol (0.05 % w/w), andCFPP (0 ◦C).

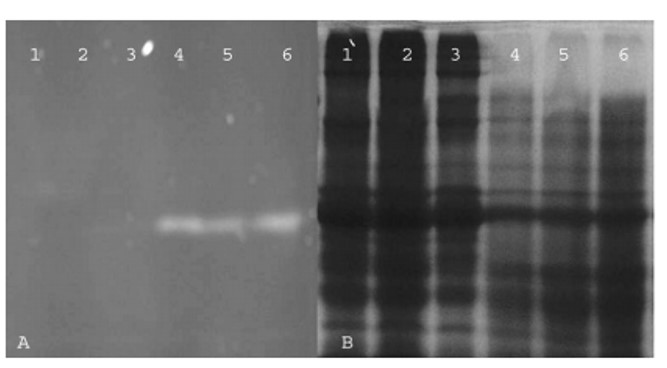

In the first figure we can see:

(A) Hydrolysis of MUF-heptanoate in buffer, Triton X-100 and Tween 80, respectively; catalyzed by VEED (lanes 1, 2 and 3) and catalyzed by VEEG (lines 4, 5 and 6). (B) Gel stained with Coomassie Blue in buffer, Triton X-100 and Tween 80, respectively; lanes 1, 2 and 3 catalyzed by VEED; lines 4, 5 and 6 catalyzed by VEEG.

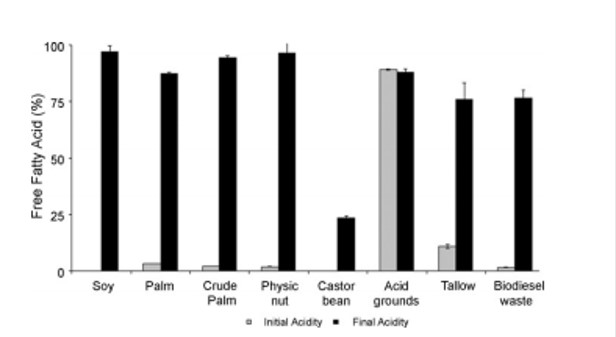

In Fig. 2. is show the following:

Hydrolysis of different biodiesel raw materials by VEEG the hydrolysis reactions were carried out with 10 % w/v of substrate, 0.1 M Tris–HCl buffer, pH 8.0, 10 % w/w of VEEG, for 2 h.

Hi! I am a robot. I just upvoted you! I found similar content that readers might be interested in:

https://www.researchgate.net/publication/222017584_Application_of_lipase_from_the_physic_nut_Jatropha_curcas_L_to_a_new_hybrid_enzymechemical_hydroesterification_process_for_biodiesel_production