3D Printing

Technological innovations have been making strides in most sectors of life, with most processes being automated, and the manufacturing industry has not been left behind with innovations like 3D printing (additive manufacturing process). Though the idea and concept of 3D printing have existed for a long time, it has been making strides in recent times.

What is 3D Printing?

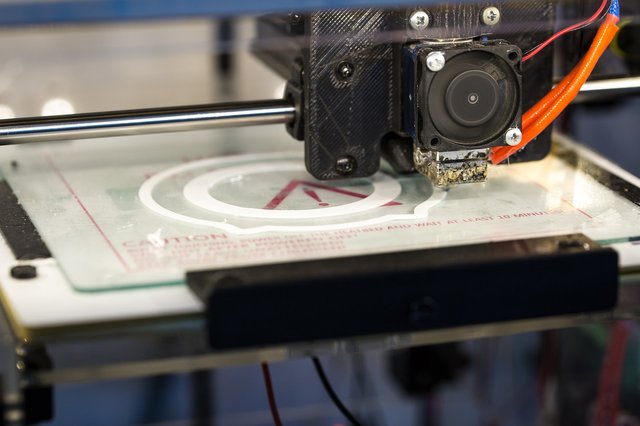

3D printing is the process of three-dimensional manufacturing objects using a digital file and a 3D printer. 3D printing, also known as additive manufacturing, adds thin layers of an object using a 3D printer until the image is fully formed. 3D printing or additive manufacturing is a shift from traditional manufacturing that involves subtraction, moulding, and boring holes to create an object. This entails that 3D printing involves the use of fewer materials when producing.

3D printing uses a digital model to manufacture a physical object by adding up layers of the material using a 3D printer. 3D printing means that complex shapes and things can be manufactured with more accuracy and efficiency than traditional manufacturing.

How Does 3D Printing Works

Several techniques are used when manufacturing an object using 3D printing, but they all follow a similar template. The starting point of 3D printing is to create or download a 3D model. A 3D model is the digital design or representation of the object to be manufactured. This is a critical aspect of 3D printing, as any error will be present in the manufactured object. There are different 3D software where a 3D model can be designed and also downloaded as a printable file (.OBJ .STL)

After creating or downloading a 3D model as a printable file, the file will go into a process called slicing. Slicing is the act of breaking down a 3D file design into different layers that can fall into the hundreds. Slicing is done on 3D slicing software. 3D printing involves adding the object material layer by layer. Slicing helps the 3D printer understand how many layers are required and should be added.

The sliced file is sent to the 3D printer, and the object is ready to be manufactured. 3D printing involves several different processes, each with its benefits and drawbacks. The various 3D processes include;

Stereolithography

Digital Light Processing (DLP)

Fused Deposition Modelling (FDM)

Selective Deposition Lamination (SDL)

Electron Beam Melting

There are different materials used in 3D printing to manufacture objects. These materials are selected by choice of object and 3D printing process employed. The 3D printing materials used include; Plastics, Metals, Ceramics, Papers, Bio-materials, etc.

3D Printing Applications

The importance of 3D printing has been felt across different industries as there have been applications of the 3D printing technology in manufacturing different objects that seemed impossible to do before. Few of the industries to apply 3D printing in the manufacturing of products includes;

- Healthcare

The health care industries have benefited from 3D printing technology. It means certain health care devices that were too complex to manufacture by traditional manufacturing process accurately are now manufactured using 3D printing. Examples of healthcare products manufactured using 3D printing include; dental products, prosthetics, and recent development hopes to have 3D printing manufacture human organs, bones, and skin.

- Automobile

The automobile industry was one of the first industries to adopt 3D printing as a manufacturing option. The automobile industry has utilized 3D printing to manufacture parts and spare parts like wheels, rims, bumpers, etc.

- Architecture

Architects usually create a prototype of projects to showcase what the actual project will look like. The architecture industries now use 3D printing to produce prototypes to give a project's actual but miniature representation.

- Construction

As earlier stated that architects used 3D printing to manufacture prototypes of buildings. The recent development of 3D printing technology has seen houses built using 3D printers. Also, sculptures are being constructed using 3D printing technology.

Benefits of 3D Printing

- Design Freedom

One of the key benefits of 3D printing is that it gives design freedom. If it can be designed, then it can be manufactured. Complex shapes and objects that were a constraint for traditional manufacturing are being manufactured with more ease than ever before.

- Little or No Material Waste

In traditional manufacturing, manufacturing an object requires that the material parts be subtracted, filed out, or holes bored into the object, all creating material waste. With additive manufacturing, objects and shapes are formed by adding the material layer by layer, and as such, only the required amount of material is being used.

- Tool-less

In traditional manufacturing, simple objects like bolts and nuts will require tools like a boring machine, a milling machine, a filling machine, etc. In 3D printing, there is no need for such tools as most objects are manufactured accurately by the 3D printer.

Drawbacks of 3D Printing

- Lower Strength

One of the drawbacks of 3D printing is that the objects manufactured through 3D printing do not have enough tensile strength to withstand certain pressure compared to objects manufactured from traditional manufacturing processes.

- High Volume Cost

When manufacturing products in high volume, 3D printing is less cost-effective when compared to producing the same objects on a large scale using traditional manufacturing. There is also concern about post-processing requirements and cost.

Conclusion

3D printing is changing how things have been done in the manufacturing industry. It has opened rooms for more innovative objects that were impossible to create using the traditional manufacturing model to be made. With applications across various sectors, 3D printing is proving to be the future of manufacturing.

hello @stealthog,

one of the uses of this technology is related to medicine as scientists are now able to print organs. i believe that in the next few years it will be very common for people to have organs printed with this type of technology, a giant leap forward for humanity.

3D printing is the new form of print which is playing an important role in manufacturing industry and I believe the best of it is yet to come however we can surely expect the significant change coming on the place very soon. Nice article

Greetings @sigiloso

3D printing is a breakthrough for many companies and every day they are finding many more parts that were thought could not be done with this technology, I hope that very soon this technology reaches more countries and that their costs are more economical and also improve the quality, strength and strength of them.

Thank you very much for sharing

Greetings my friend. I loved this publication, I congratulate you for the good content, presentation and writing. This topic is extremely interesting; it seems to me a solution to many current problems of society; let's hope it can be implemented on a larger scale. Blessings!

@zmoreno Thanks for the nice words.. motivated to do better..

Big ups to you and the sevengers team

hi @stealthog

Can you check your discord DM? I've tried to reach out to you, but I'm not sure if I've messaged correct person :P