Predictive Maintenance

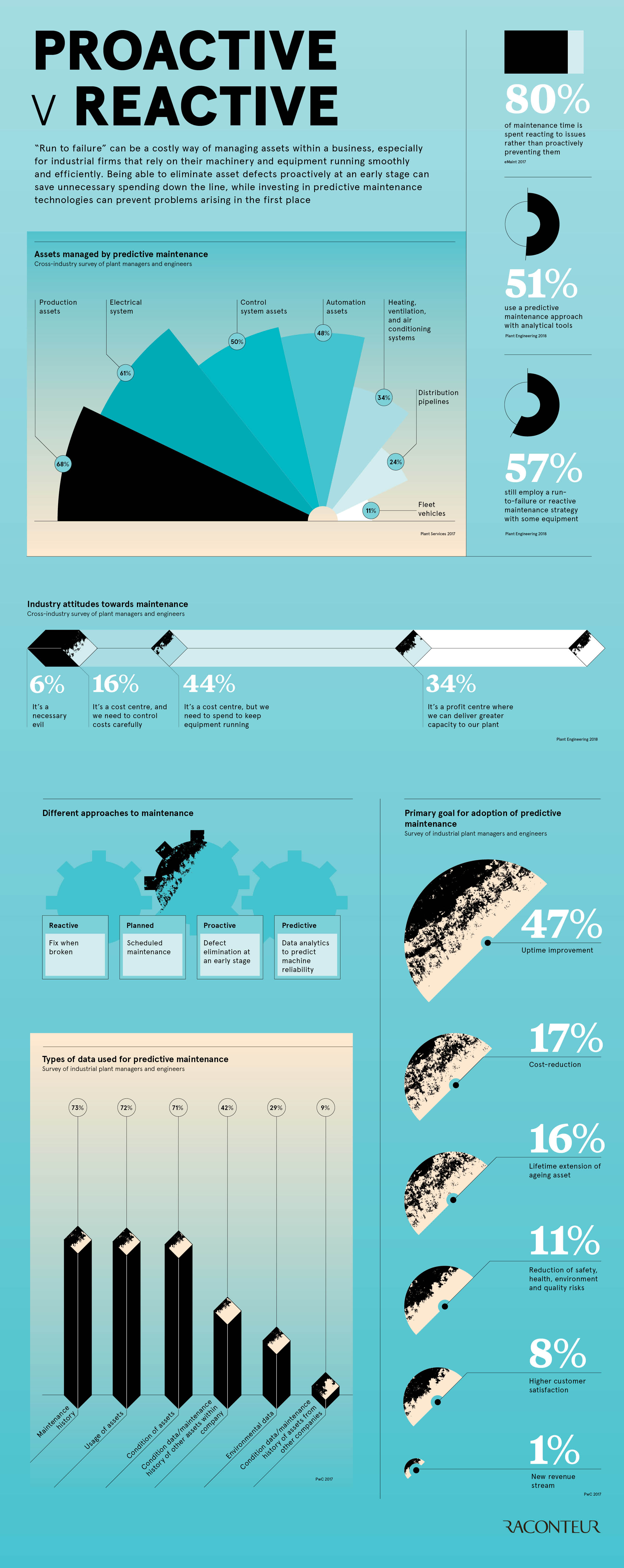

Techniques are designed to help determine the condition of in-service equipment in order to predict when maintenance should be performed. This approach promises cost savings over routine or time-based preventive maintenance, because tasks are performed only when warranted. “Run to failure” can be a costly way of managing assets within a business, especially for industrial firms that rely on their machinery and equipment running smoothly and efficiently. Being able to eliminate asset defects proactively at an early stage can save unnecessary spending down the line, while investing in predictive maintenance technologies can prevent problems arising in the first place.