3D Printing and How I Purchased My First 3D Printer and Started My Journey Creating my Designs

3D printing was created in the 1980s. Back then it was only used for testing. There are 3 reasons for printing. Retail, Business and Testing. There are nine types of 3D printing technology:

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Fused deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- Selective Laser Melting (SLM)

- Electronic Beam Melting (EBM)

- Laminated Object Manufacturing (LOM)

- Binder Jetting (BJ)

How do 3D printers work?

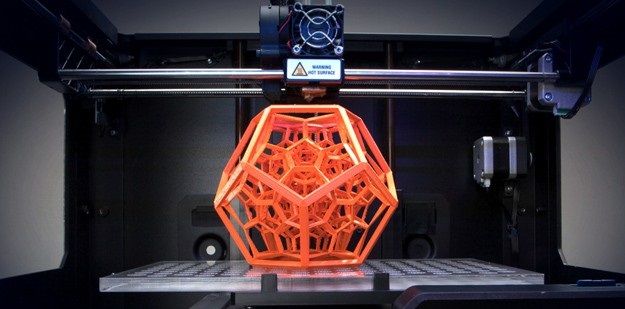

3D printers use filament. FDM printing works by depositing any type of filament bottom to top. It deposits in Micro layers until the object is formed.

Filament Types

There are many types of filaments but the most common is PLA and ABS. Although you can print with practically anything. For instance, TPA bendable durable filament. You can also print with Thermochromic material, meaning color changing with temperature. Also glow in the dark filament. There are also material based filaments like Iron or wood filament.

Factors to consider when buying a 3D Printer

- When buying a 3D printer the number 1 thing to look at is the reviews. You want to see if there are minor problems or big problems from the experience of other users.

- Most likely if the Printer is 3 and a half stars and below it is not such a good printer. Read about the printer you are getting. It is a good idea to first read about the printer you picked and if you are really going to use your 3D printer .

- Any printer that is on your list should have self leveling of the plate or the printer will dispose filament too high or too low and will not print correctly.

My personal experience with 3D printers

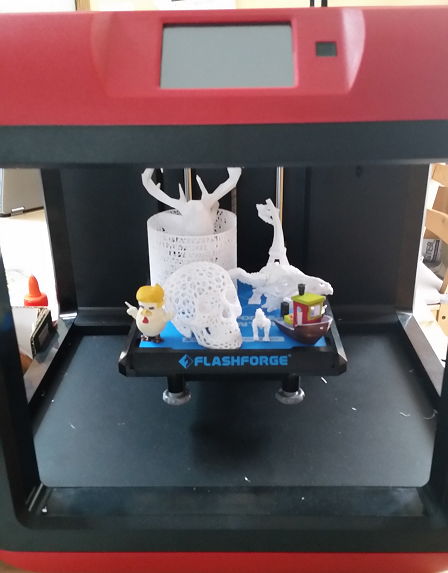

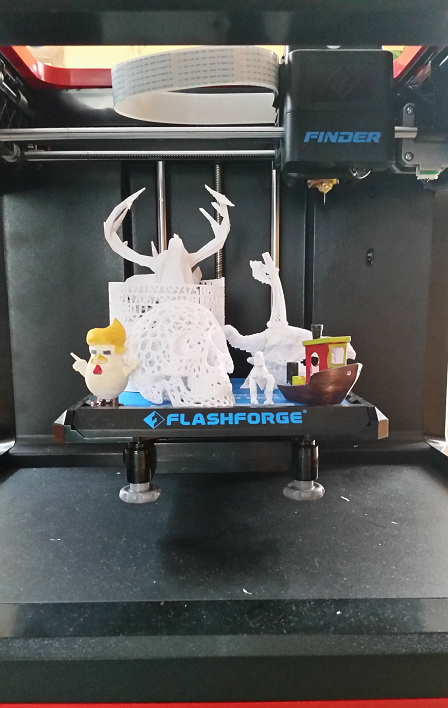

The first printer I bought was based on the price. I looked for the cheapest printer I could find online and ordered it. It was a printer made in China and it never printed a single item. The nozzle simply scratched into the plate. Luckily, I was able to return it for a full refund. Then I spent some time reading up the reviews from printers others bought. And settled on the Flashforge Finder as reasonably priced and likely to work for me. I bought it and was able to set it up within 30 minutes and started printing. The above pictures show my printer and some of the items I have been able to print from it since I set it up.

Good Printer Costs

Just because the printer is high in cost doesn't mean it is good. For instance the Maker bot is about $2,000 printer and its ratings from those who bought it is kind of low. We got the FlashForge Finder which was $400 and in its online rating was better then the Makerbot. There are some Printers with a cost of $300 and below but don't have as much quality and wont last as long.

Printing Hack/Tricks

When printing an object you can pause in the middle which enables you to do many cool things. When we were printing a whistle, for instance, we paused it to put a ball inside to add the sport's coach whistle effect. Alos, to make something magnetic you can pause the printer and place a magnet inside. When printing you can pause and put anything in it.

So now I have started the next step in printing my own inventions. I will be sharing pictures of them here and how those are progressing.

If you enjoyed this article, upvote it 100%, and let me know in comments below. ---

This article was written by my 10 year old son. He is an avid consumer and investigator of new technology and just obtained his first 3D printer about three months ago. Since this blog is about all things technology and I couldn't yet have him create his own blog, I offered to have him write in mine. This article has not been edited at all. And I will continue to write about fintech and cryptocurrencies as well as genetic algorithms. (This slightly different article is not because of the fallen prices of crypto, which you will notice this blog well expected and predicted going back to two months ago, and earlier in other forum.) But I hope those who are into 3D printing or looking to get their first 3D printer would find this helpful and informative.

As my own addition, I think 3D printing going into the future, as the prices come down, could make custom parts cheaper to make relative to the cost of shipping them. This would reduce the effect of cheaper labor costs that drive manufacturing from regions with greater cost of living but higher consumption to regions with lower living costs. Long term, it also continues the shift towards greater automation, productivity, and less labor - a setback to less skilled labor. It remains to be seen if the labor force can continue to adapt to catch up with these changes in the skill sets that are being required. On the flip side, it could foster greater innovation as the distance between concept and prototype reduces with the tool it provides.As usual all relevant comments will be upvoted.

Your son writes very well! I think he could have his own spot writing articles on @steemiteducation about technology and it might ease some parents' mind about how we can teach children to be the ones to drive a positive change in our perception and use of technology in education :)

I have only just got into pixel art and the goal is to be able to print my own designs using a 3d printer... a long way to go I know, but I might have to get some tips and advice from your son :)

Also, you might be interested in @steemmakers, which is a group for diy/makers, and @thesteemhouse, which is a maker space that will hopefully give Steemit another physical presence and contribute to the spread of new ideas and projects!

Thanks! I was not aware of those resources. I will check them out. And thanks for the kind comments. He was quite happy to read them.

Nice article. I had one nitpick to make and also wanted to share an experience i had commercially with 3d printing.

FFF (Fused filament fabrication) is the more popular term nowadays to describe FDM technology as it is devoid of copyrights.

I just wanted to mention an interesting experience i had with FDM. i used to consult with a mechanical engineering company and they were making pill presses for a customer who used to sell homeopathic medicines. the pill press used to churn out compressed tablets that would then be wrapped in butter paper.

The pill press had several moving components like punch dies, punch levers, crank shaft, positioning wheel, drift pins and so on. It suffices to say that the customer interaction was an expensive affair because they had to make a fully operating machine to match their specs, let them test it, make modifications and then actually insert it into production. this whole process would take months with severe cost implications.

One of the engineers did some research and found this company called stratasys. They decided to create a hand operated prototype and stratasys built it for them using thermoplastic in 2 days. the engineers the assembled the prototype together and were able to cut the entire design-verify-post production cycle to just a week. the accuracy of thermo plastic was within 2.5% of the actual production components which were made of steel.

FFF (or FDM if you prefer) is a great prototype maker

Have you considered also getting a plastic grinder to crush up plastic that would usually be waste and make it into printable filament? Fully Recycle! ha!

Great post

It is amazing how many things you can make with a 3D printer

a friend has a small 3D printer at home and he use it to print his fake bate to fish , he then paints them and varnish and put hooks on it with lead or other weight inside to float or sink. Pretty cool material but you do have to draw it first so if you don't have experience with that it's expensive to just try and make mistakes or so ;)

My son wants to get one , but most of them were very expensive. I’m going to look into this printer. Thank you .

You are very welcome. We did go through a few iterations and studying and made a few mistakes. Hopefully, this helps to avoid some of those.

The 3D printer is a bit expensive. There was an exhibit here in the UAE about modern technologies and one with that 3D printer. Creating or printing is long, it takes some time before it's finished. And it depends on how large it is before printing ends. You can also print anything in the different colors you like.

Technology is really different now. The level of education is too high! Hopefully they do not exceed their limitations so as not to violate God's law.

To listen to the audio version of this article click on the play image.

Brought to you by @tts. If you find it useful please consider upvote this reply.

Congrats! This post was resteemed and upvoted by @puppybot!

Send 0.400 SBD or 0.400 STEEM to @puppybot with your post URL in the memo. Get your post resteemed to 4000+ followers and get a minimum of 20+ upvotes!

Want to learn more? Click here!

Wonderful post ..thanks for sharing...Best of luck friend ✫resteemid

this is the best bot for steembottracker clik here https://steemit.com/bots/@hassanbenali/the-best-bot-for-service-how-to-create-steem-bot-tracker

Transfer 0.200 SBD or 0.250 steem to @mrbean1 and put the link of your post in the public memo you get 5 good UPVOT and resteem by @mrbean1 +followers