Hydraulic Structure; Culvert

When we talk about keeping our environment clean, healthy, safe and secured, one of things that comes to mind is good roads and good drainage system.

One of the good drainage system is A Culvert. One of the three types of hydraulic structure in engineering.

A culvert is a hydraulic conduit which is designed to convey the flow of a stream through any obstruction to its course such as roadways, embankments etc.

Culverts can be constructed in different shapes and configurations. Factors for selection of these properties include the roadway profiles, flood evaluation and maintenance cost. Culverts are also constructed from variety of materials.

Shapes

In principle, the selection of the culvert’s cross-sectional shape is based on cost of construction, embankment height, upstream water elevation and hydraulic performance. The most commonly used shapes include arch, rectangular (also called ‘box’), circular, pipe-arch and elliptical. A few has been depicted in the figures below.

Inlets

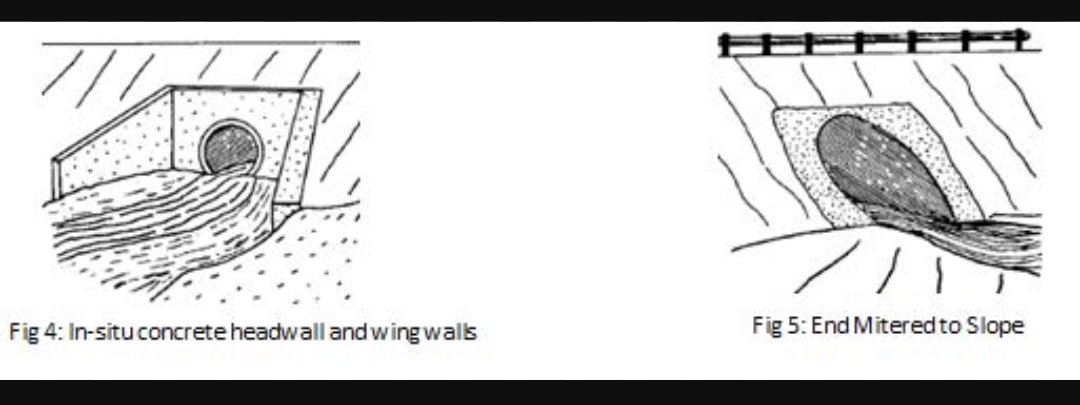

Different kinds of inlet configurations are usually used on culvert barrels which includes in-situ (constructed on site) and precast (prefabricated) installations. Common types of inlet configuration includes projecting culvert barrels, in-situ concrete head walls, culvert ends mitered to conform to fill slope and precast end sections. Other considerations are structural stability, control for erosion, fill retention and aesthetics.

Selecting the appropriate inlet section can greatly improve the hydraulic capacity of a culvert. Providing a gentle or gradual flow transition will lessen the energy loss and therefore create a more efficient inlet condition.

Material

Selection of material for a culvert depends upon structural strength durability hydraulic property known as ‘roughness’, abrasion and corrosion resistance. Concrete, corrugated steel and corrugated aluminum are the three most common materials used in construction of culverts. Asphaltic concrete may be used as a liner inside a corrugated metal culvert. Lining a culvert with other materials

CULVERT HYDRAULICS

Theoretical analysis of the hydraulics of any particular culvert installation is time consuming and may prove to be difficult since flow conditions vary for different culverts and vary over time for a given culvert. For example, the barrel of any given culvert may flow at full or partly full capacity depending on downstream and upstream conditions, inlet geometry and barrel characteristics.

Flow Conditions

Full Flow – This is also known as pressure flow and it is the hydraulic condition where a culvert is flowing full. Flow would expand if cross-sectional area of culvert in pressure flow were increased. Back pressure caused by a high downstream water surface elevation is one condition that creates which creates pressure flow. A high upstream water surface elevation may also produce pressure flow.

Partly Full – This is also often referred to as Free Surface Flow r open channel flow and may be categorized as subcritical, critical or super-critical.

this is very informative. I just added more random knowledge to brag about when this topic pops up. :)

Congratulations @neebootoo! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOPInteresting information. I never really thought to much about drainage systems. I enjoyed learning about this :)