Why are tankers that haul liquid cylindrical? Can't it be, say, rectangular?

You must be familiar with truck tankers that ferry all types of liquid/fluid through the highway and our neighbourhood. The liquid product may either be liquefied natural gas (LNG) such as methane or ethane, crude oil, petroleum products such as tar, petrol, kerosene, etc. and industrial chemicals. Some are pressurised and others non-pressurised. But they all have one thing in common; they are cylindrical or elliptical.

[Image Credit]Pxhere: A Truck Tanker

Why is the size not rectangular seeing that manufacture of these cylindrical tankers is not as easy as it would have been to produce the rectangular tanker?

First on the reason why cylinder shaped tanker is the choice of all tankers is the strength. Cylindrical tankers have no weak spots that may require reinforcement. The corners of a rectangular tanker are its most vulnerable point concerning its ability to withstand pressure. Comparatively, the rectangular tank would fail faster under pressure than its cylindrical counterpart.

That is the same reason airliner's windows are oval. |

In the early days of aviation, the first commercial airliner de Havilland DH 106 Comet have large square windows.

Due to the pressuring and the depressuring of aircraft, the fuselage is under pressure, and a square window corner experiences thrice the pressure compared to the rest of the aeroplane. This continuous high pressure leads to the aeroplane body experiencing fatigue.

In 1954, the Comets jet experienced two fatal aircraft involving flight 781 from Rome that disintegrated after 20 minutes after takeoff and Flight 201 from London to South Africa that ended up crashing into the Meditarian Sea near Naples.

The cause of the crashes investigations revealed to be from the square windows.

You can take a look at this short animation analogy from the Federal Aviation Administration (FAA) here that showed how the square window builds up pressure on the plane's body.

The rectangular tanker has the welded joints in the four corners as its weak spots that will fail on continuous pressure. Therefore the cylindrical tanker is more immune to failure from corners since it has none.

Sloshing: Sloshing is the movement of liquid contents on a tanker that is not full. The action is as a result of inertia, the tendency of a body to continue in its present state of motion. A cylindrical container reduces the effects of these "surges" in liquid. Though in some tankers they install baffles which are a liquid-restricting solid divider (with holes in them) that are placed in multiple places inside the tanker to reduce the sloshing effect.

Experienced tanker drives do not come to an abrupt stop and tend to maintain the same level of speed while accelerating or slowing down to reduce sloshing effect.

The big liquid movement could create a high impact pressure on the tank which may lead to structural damage.

Stability: This is a critical requirement of the tanker. The centre of gravity of a cylindrical tanker is lower than that of a rectangular tank; that makes the former to be more stable than the latter.

Wikipedia CC-BY-SA-4.0 by Sinotrailer: A cement tanker with sloped bottom to enable ease of cement evacuation

Ease of liquid evacuation: The cylindrical shape tankers makes extraction very easy. The liquid can easily be channelled down to the bottom of the tank especially if the tanker is designed like on this tanker on the left which is usually employed in cement haulage.

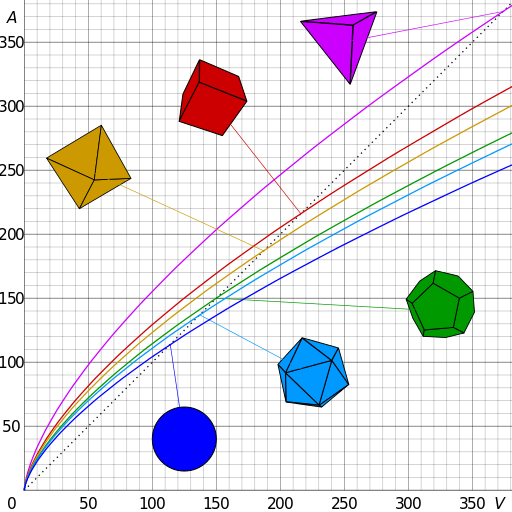

Economics/ Ease of Maintenance: A cylindrical tanker will contain the maximum volume of any liquid product with the minimum amount of material. The cylinder has the least circumference to area compared to the rectangle.

Wikipedia CC-BY-SA-3.0 by Cmglee:Graphs of surface area, A against volume, V of the Platonic solids and a sphere. The surface area decreases for rounder shapes, and the surface-area-to-volume ratio decreases with increasing volume.

So to create the large containers of equal volume, there would be less material for a cylinder than a rectangle.

Due to the corners inherent in the rectangular tanker, cleaning and maintaining it is difficult as liquids and fluid can get stuck at the corners. But the cylindrical truck is easy to cleanup having no edges.

REFERENCES

Sloshing characteristics in half-full horizontal elliptical tanks with vertical baffles

Scientific Reason for Round Windows on Planes

The tragedies that changed the shape of plane windows forever

Why Do Liquid-Carrying Trucks Have Cylindrical Shaped Tankers?

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details. You can also check this blog post by @steemstem here and this guidelines here for help on how to be a member of @steemstem. Please also check this blog post from @steemstem on proper use of images devoid of copyright issues here

Square windows on a plane! Never knew that :)

Now, it seems SO obvious 😅.

I like very much the way you manage to pack a lot of interesting info in a concise way @greenrun. I must learn that from you 😊.

Lots of love to you Green :)

Thank you for the compliment. We all learn from each other :)

That is the beauty of steemit.

I liked this post, I pretty much knew the why of it, but it was still a fun read. Sometimes complicated is not to hard. One other side benefit of cylindrical shape is the wind effect, not just the wind as it travels the road, but because of the shape the side blast of wind move more easily around it instead of right against it, so less chance of the wind causing the trailer to flip onto it's side.

Yes, I think so too. The cylindrical shape will have an aerodynamic effect. If you take a look here you'd notice that the rectangular box has the highest drag coefficient.

Well, i think i should add this.

To make a rectangular shape, the tanker would need to be joined (welded) in 12 (or more) distinct places but in the case of a circular one, just 3 places is possible. Thus, lesser work is done in production and lesser weak points.

The more the number of joints, the greater the weak point of a device.

This is good.

It had never really come to mind despite the fact that I pass tankers daily on the road but once I saw this I knew I had to read up.

I agree on the pressure generated weak spots. In a general sense, the cylinder provides a more sturdy figure than most shapes

I agree with you. It is the best shape to use.

This is cool. I'm wondering if they might be a way to relate cylinder and rectangular tanker to pressure formular?

There's already an existing relationship between volume and pressure. Thank you.

Yes, obviously. I meant in relation to what your article is saying about why cylinder are used? Don't mind me.

lolz @greenrun cos no one would ever imagine how it would look like seeing manufacturers produce a rectangular tanker? however its an idea what considering. however you should consider the roads this rectangular tankers would use, for if they are rectangular in shape, it would be needing a different road construction to fit its new shape as well.

for me i believe to much is at stake for a rectangular tanker

We already have a rectangular box truck, so a rectangular truck tanker won't look so much out of place :)

thanks for this, very educative.

Thank you.

Another amazing post. Thanks for sharing

Thank you for reading.

Wow...and i thought i knew all about Petroleum and hydrocarbons as a biochemistry student, turns out i dont...

Thanks @greenrun for this amazing piece of information..

Steem on..

Stay awesome

That's the chemistry, you'd need to check more on the physics part of it :)

In addition to what nicely said, I'll also say that cylindrical shapes are more streamlined than rectangular shapes

I agree with that.